Early Bug Detection & Parallel Development

Shorten development cycles and allow multiple developers to work simultaneously.

Modern automotive ECU software is increasingly complex, and testing after hardware completion often leads to delays and high costs. GSIL solves these challenges by enabling early-stage verification — without hardware.

Software-in-the-Loop Simulation (SILS) allows developers to test ECU application source code — whether handwritten or auto-generated from Simulink — on a PC before hardware is ready.

Benefits include:

Shorten development cycles and allow multiple developers to work simultaneously.

Automated exhaustive testing ensures reliability without extra tools.

Integrate static analysis, virtual ECU generation, testing, and coverage measurement.

Minimal manual code changes, automatic stub generation, and link error resolution.

DLL-based virtual environments ensure secure sharing between OEMs and suppliers.

GTrainer offers a software-only learning package — no hardware required.

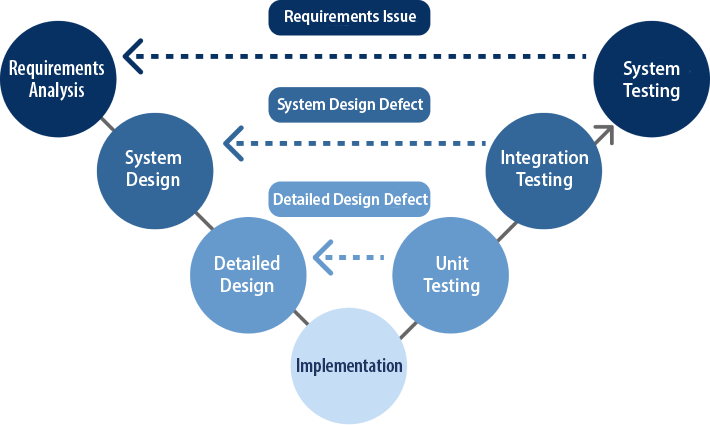

In automotive ECU software development, the V-model is commonly used. The later a defect is discovered in the process, the more steps need to be redone, resulting in significant rework costs.

The graph illustrates the cost of fixing a single defect at different development phases. Before implementation, the cost is relatively low, but it skyrockets after testing begins.

In particular, if a defect occurs after mass production and leads to a recall, it causes enormous costs and damages brand reputation. Therefore, detecting and fixing defects as early as possible is essential. This concept is known as front-loading or shift-left.

SILS enables verification of ECU application source code--automatically generated from MILS models--on a PC, and supports CI-based automated testing. By allowing easy, automated code verification before hardware completion, SILS makes software development and testing more efficient, reduces workload, and helps control rework costs.

Rework man-hours for bug fixes in the V-model

Correction cost per defect at each stage of development

Learn more about GSIL's features and use cases through our on-demand webinars. To watch the videos, please register using the link below.

Watch GSIL Demo Videos(Currently available in Japanese only)

*HILS (Hardware-in-the-loop simulation) : A simulation method that uses an actual control device (ECU) together with a simulated controlled system.

Annual maintenance includes technical support, vECU build services, CI assistance, and training.

Explore GSIL's features and use cases through our on-demand videos.